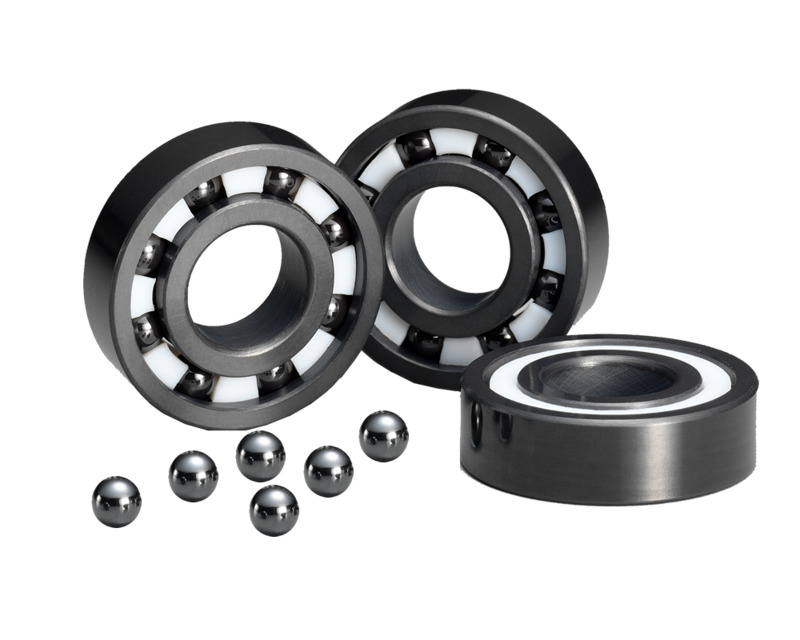

For decades, steel has been the undisputed king of bearings. However, a new material is rising through the ranks: ceramic. Ceramic bearings offer a range of advantages that are revolutionizing industries, prompting many bearing manufacturers to explore customized ceramic solutions. Let’s delve into the world of ceramic bearings and understand why they’re making such a big impact.

Ceramic bearings boast an exceptional hardness, leading to bearings that resist wear and tear significantly better than their steel counterparts. This translates to longer lifespans, reduced maintenance costs, and improved overall efficiency. Additionally, ceramic exhibits superior dimensional stability, minimizing size variations due to temperature fluctuations, crucial for precision applications.

Traditional bearings struggle in harsh environments. But not ceramic. Their inherent corrosion resistance makes them ideal for applications exposed to saltwater, chemicals, or extreme temperatures. From the frigid depths of space to the searing heat of industrial furnaces, ceramic bearings operate flawlessly, ensuring equipment reliability in demanding situations.

Compared to steel, ceramic offers a significant weight advantage. This is a game-changer in weight-sensitive applications. The aerospace industry, for instance, leverages ceramic bearings to reduce overall spacecraft weight, maximizing fuel efficiency and payload capacity.

Many leading bearing manufacturers understand the unique needs of different industries. They offer customized ceramic bearing solutions tailored to specific applications. This customization can involve factors like size, shape, lubrication options, and even the specific type of ceramic used (silicon nitride or zirconia). This level of customization allows engineers to optimize performance and unlock the full potential of ceramic bearings in their designs.

For many industries, ceramic bearings are a strategic investment. Their superior performance, extended lifespans, and ability to operate in harsh environments often outweigh the initial cost. Additionally, customized solutions from leading bearing manufacturers ensure a perfect fit for specific needs, maximizing the return on investment.